Surface engineering of oil and gas fields

Core Technologies and Services:

1. Natural Gas Purification and Treatment

[1] Amine Sweetening: Utilizes mixed amine (MDEA) or proprietary amine solutions to efficiently remove acidic gases (H₂S, CO₂) from natural gas, meeting pipeline transportation or liquefaction requirements.

- Capacity: 1,000–500,000 m³/h

- Output Specifications: H₂S<4 ppm, CO₂ <50 ppm

- Adaptability: Tailored process combinations for gas sources with high/low CO₂ or impurities.

[2] TEG Dehydration Technology: Triethylene glycol (TEG) adsorption under high pressure and low temperature reduces water content in product gas to<7 lb/MMSCF. Intelligent simulation optimizes solvent consumption.

2. Natural Gas Liquefaction (LNG) & Light Hydrocarbon Recovery

[1] Mixed Refrigerant Cycle (MRC): Integrates pretreatment, cryogenic liquefaction (-162°C), and storage to produce high-purity LNG (H₂S<3.5 mg/m³, H₂O <1 ppm). Daily capacity: 10,000–5,000,000 m³.

[2] Light Hydrocarbon Recovery: Innovative processes (e.g., expansion refrigeration, GSP/DHX) achieve >95% C2 recovery rate, maximizing resource value.

3. Sulfur Recovery & Tail Gas Treatment

[1] Claus Process & Tail Gas Purification: Multi-stage Claus reactors or hydrogenation reabsorption recover sulfur (2–500 t/day) with 99.8% efficiency. Near-zero emissions, adaptable to acid gas containing NH₃, HCN, etc. Co-generates high-pressure steam to reduce energy consumption.

4. Crude Oil Treatment & Produced Water Re-Injection

[1] Crude Stabilization: Process chain (three-phase separation → electrical dehydration → vacuum flashing) produces commercial crude with<0.5% water content.

[2] Produced Water Treatment:

- Efficient oil removal via hydrocyclones (80–90% efficiency), compact flotation units (CFU), and coalescence separation (CPI).

- Smart chemical dosing (reverse demulsifiers, desulfurizers) combined with walnut shell/dual-media filtration ensures reinjection compliance.

5. Digital Engineering & Lifecycle Management

[1] Smart Design Tools: ASPEN HYSYS, PDMS, and other software for process simulation, 3D plant design, and pipeline stress analysis.

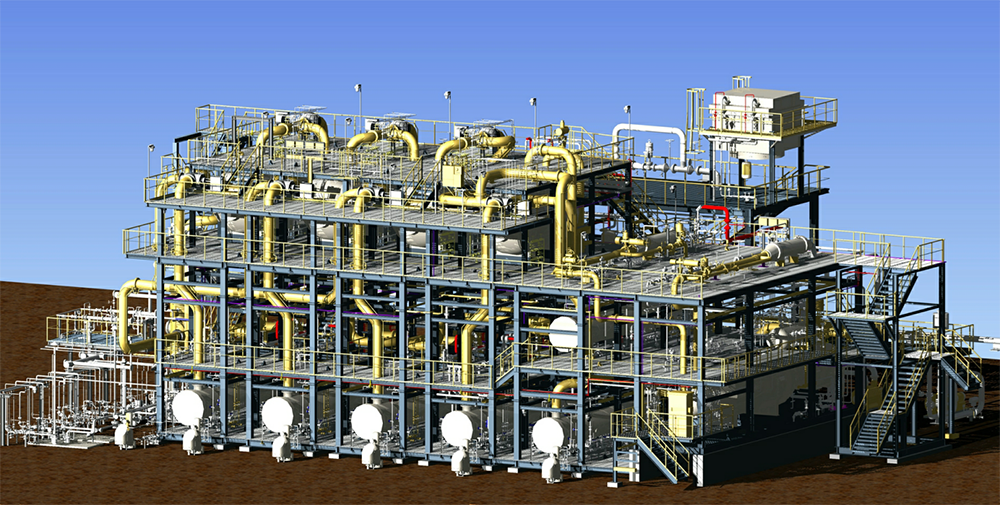

[2] Modular Delivery: Skid-mounted and prefabricated units reduce project timelines by 40% and on-site risks.

Success Cases:

- Yadavaran Oil Field, Iran: CPI coalescers + walnut shell filtration achieved crude oil water content<0.5%.

- Saudi Aramco CO₂ Dehydration Project: TEG technology reduced gas moisture to industry-leading levels.

- Liuhua 16-2 Oil Field, China: Hydrocyclone skids efficiently treated high-oil-content produced water.

- Liwan 3-1 Gas Field: CFU compact flotation units improved wastewater treatment efficiency, reducing chemical usage by 50%.

Why Choose Us?

1. Technological Leadership

- Internationally certified core technologies (e.g., amine sweetening, MRC liquefaction) adaptable to complex conditions.

2. Environmental Efficiency

- 99.8% sulfur recovery rate, >95% produced water reinjection rate, supporting green oilfield development.

3. Cost Optimization

- Modular designs reduce capital investment; smart O&M lowers long-term costs.

4. Global Expertise

- Services span the Middle East, Central Asia, Southeast Asia, with deep local market insights.

Chengdu New Environment Energy Technology empowers your projects with customized solutions, rapid response, and full lifecycle services—whether building new oil/gas facilities or upgrading existing ones.

Efficient Energy Solutions for a Sustainable Future.

Gas preparation

Gas preparation

Separation and Purification Technology

Separation and Purification Technology

Engineering equipment and complete sets of technologies

Engineering equipment and complete sets of technologies