Gas purification, detoxification and deoxidation

Technical Specifications

Processing Capacity: 45,000 Nm³/h ~ 100,000 Nm³/h

Operating Pressure: ~0.5 MPa

Operating Temperature: Maximum 350℃

After Purification: O2 ≤ 100 ppm, Benzene ≤ 1 mg/Nm³, Naphthalene ≤ 1 ppm,Tar ≤1 ppm,

Hydrogen cyanide ≤ 1 ppm, Hydrogen halide,no other impurities

Technical Features

Adopts proprietary catalyst to reduce the oxygen content of sulfur-containing coal gas from 5,000 ppm to below 100 ppm under the condition of 5% low hydrogen.

Uses proprietary catalysts, adsorbents, and detoxifiers to remove harmful tar, benzene, naphthalene, hydrogen cyanide, chlorides, fluorides, bromides, etc. in coal gas to below 0.1 ppm.

Typical Project:

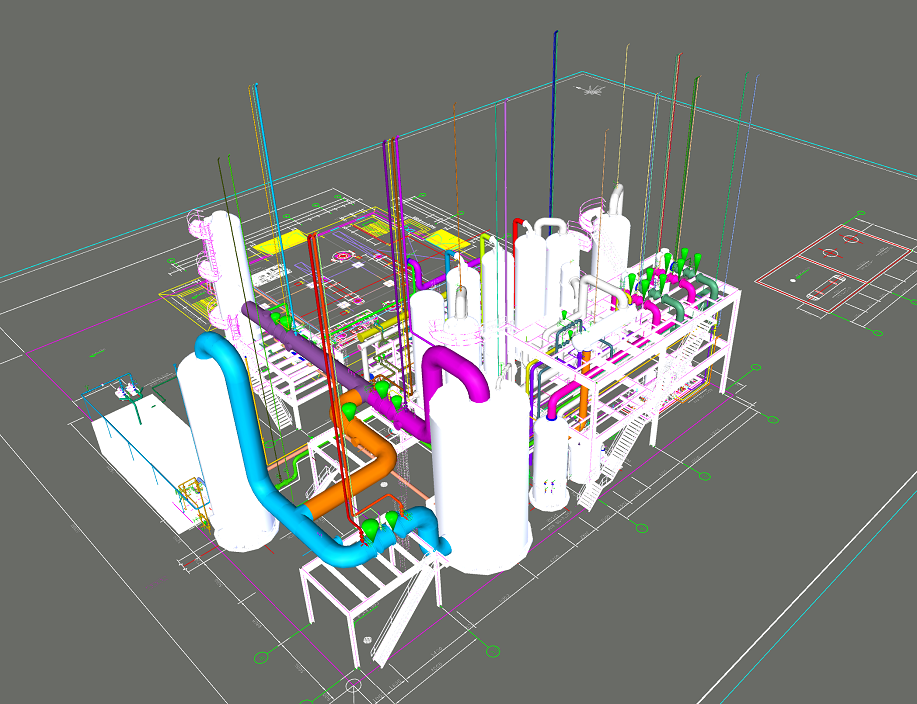

50000 Nm³/h Electric Tar Precipitator and Water Washing Dust Removal, Desulfurization, Deoxidation, and Cyanide Removal Purification Device for Metallurgical Tail Gas ( Commissioning time: June 2023; Guizhou, China)

Advanced treatment of complex industrial gasesI

Advanced treatment of complex industrial gasesI

Gas purification, detoxification and deoxidation

Gas purification, detoxification and deoxidation