Dehydration

View :

Update time : 2025-09-04

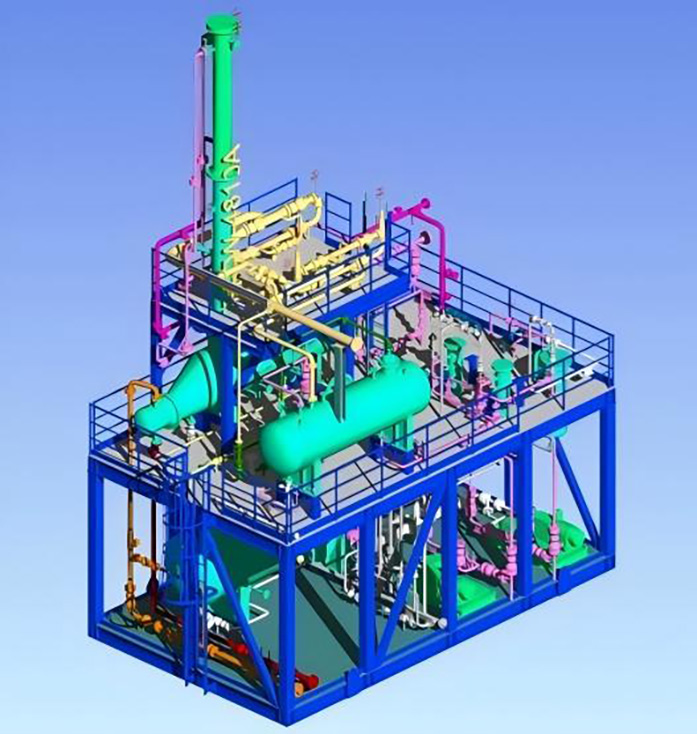

The TEG dehydration process realizes natural gas dehydration through triethylene glycol (TEG) solvent: uses the water adsorption property of TEG under high pressure and low temperature to absorb water in natural gas, then removes solvent water through pressure reduction and heating processes to complete the TEG regeneration cycle.

Processing Capacity: 1,000 ~ 500,000 m³/h

Operating Pressure: 0.5 ~ 15 MPa

Product Gas Moisture Content: < 7 lb/MMSCF

Core Advantages:

Adopts cutting-edge simulation software to optimize the process, significantly reducing TEG loss

Precise process design, convenient and efficient operation and maintenance

中海油天然气TEG脱水装置 (团队业绩)

Related News

View More >>

Organic Sulfur Removal

Organic Sulfur Removal

09 .04.2025

技术规格处理规模:15104Nm3/d ~50104Nm3/d 工作压力:2.0~3.5MPa。工作温度:50℃。总有机硫(以S计)20mg/Nm3(其中硫醇8

Desulfurization and Decarbonization

Desulfurization and Decarbonization

09 .04.2025

以 MDEA 等碱性溶液为吸收剂,通过气液充分接触实现酸性气体转移, 同时脱除硫化氢及二氧化碳。技术参数 处理规模: 1000 Nm3/h ~50104

Sulfur Recovery

Sulfur Recovery

09 .04.2025

常规克劳斯 / 低温克劳斯工艺与尾气还原吸收系统以富天然气和油田伴生气为原料,通过单种或组合工艺(如中压氨 / 丙烷制冷、JT 阀节流 / 膨胀制冷、混合制冷剂